Discover the seamless fusion of tradition and technology in clothing manufacturing with a guided tour of Kiton’s Napoli factory, highlighting the pivotal role of ERP systems in ensuring precision and quality at every stitch

In the bustling streets of Napoli, Italy, lies a gem of craftsmanship and tradition – the Kiton factory. Nestled amidst the vibrant cityscape, this renowned establishment stands as a testament to the artistry and precision that define Italian tailoring. Recently, I had the privilege of embarking on a guided tour of this illustrious facility, led by none other than the factory manager herself.

As we stepped into the heart of Kiton’s manufacturing hub, I was immediately struck by the meticulous attention to detail that permeated every corner. Our journey began at the inception of the manufacturing process, where raw materials were transformed into exquisite garments. Guided by Ida, we traversed through each stage, gaining invaluable insights into the inner workings of this renowned brand.

One of the most intriguing aspects of our tour was the integration of technology within the traditional craftsmanship. At certain work centers, the ERP system, played a pivotal role in ensuring the highest standards of quality control. With a few keystrokes, the factory manager could access real-time data and perform final checks, ensuring that each garment met Kiton’s exacting standards before it left the premises.

For prospective ERP users in the clothing manufacturing industry, this integration of technology with traditional craftsmanship serves as a compelling case study. The ability to monitor and manage the production process in real-time not only enhances efficiency but also allows for greater flexibility and agility in responding to customer demands.

The role of ERP in facilitating communication and collaboration across different work centers cannot be overstated. Each work center at Kiton is led by a master tailor, whose expertise is honed through years of onsite education and experience. By leveraging the ERP system, these master tailors can seamlessly coordinate their efforts, ensuring that every stitch is performed with precision and care.

The emphasis on handcrafted techniques underscores the importance of ERP in preserving the integrity of the final product. In an age where mass production reigns supreme, Kiton’s commitment to artisanal craftsmanship sets it apart. With ERP serving as the linchpin of this manufacturing process, each garment is imbued with a sense of authenticity and quality that is unrivaled in the industry.

As our tour drew to a close, I couldn’t help but marvel at the seamless synergy between tradition and technology that defines Kiton’s manufacturing ethos. From the skilled hands of the master tailors to the watchful eye of the ERP system, every aspect of the production process is harmoniously orchestrated to deliver unparalleled excellence.

Visiting the Kiton factory in Napoli, Italy, served as a poignant reminder of the transformative power of technology in preserving age-old traditions. For businesses in the clothing manufacturing industry, embracing ERP is not just a matter of staying competitive but also a testament to their commitment to craftsmanship and quality. Kiton stands as a beacon of inspiration, showcasing how the marriage of tradition and technology can create truly exceptional experiences for discerning customers worldwide.

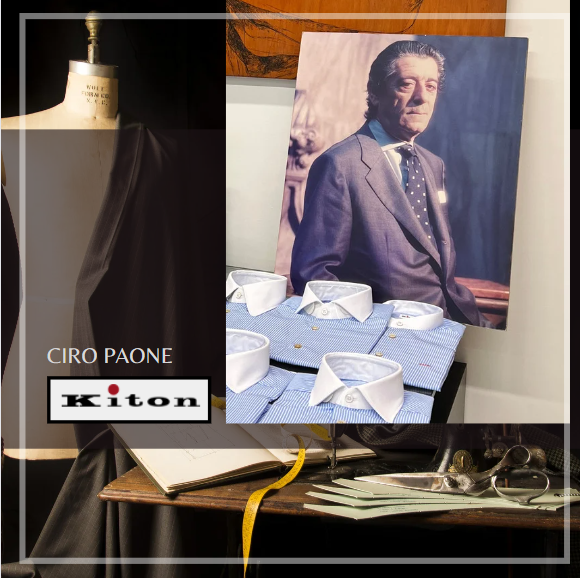

Ciro Paone was an Italian entrepreneur and the founder of Kiton, a renowned luxury clothing brand based in Naples, Italy. Born in 1934, Paone was instrumental in establishing Kiton as a symbol of sartorial excellence, known for its meticulous craftsmanship and attention to detail. Under his leadership, Kiton became synonymous with high-quality tailored menswear and expanded its presence globally. Paone's dedication to preserving Neapolitan tailoring traditions and his relentless pursuit of perfection earned him recognition as a visionary in the fashion industry.